Springs are widely used in life. From the semiconductor industry, mobile phones, computers, instruments, machines, cars, trains, and ships, springs can be seen, mainly relying on their characteristics of energy storage, conversion and pressure release. The use of such characteristics, the springs are more economical, so it can be used for a long time and widely, and always be the key components of most of devices.

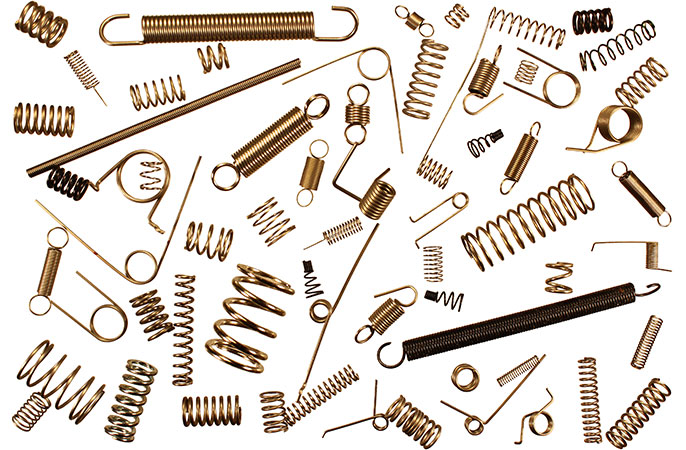

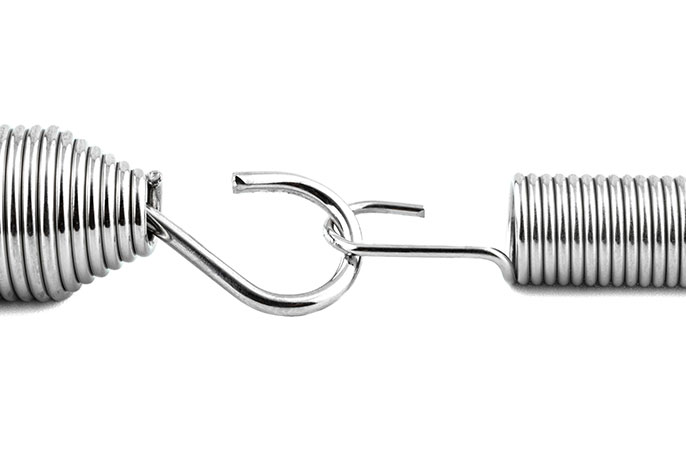

Generally speaking, in a narrow sense, the products coiled from metal round wires are wound into many turns considered the springs. If it is recognized in a broad sense and presented in a different material or shape, as long as its structure can exert the characteristics of energy conversion, it can be classified as springs category. In terms of spring materials, they can be divided into two categories: metal and non-metal. For metal springs, they can be divided into two categories: wire and sheet. Metal springs can be divided into nine categories according to their shape:

The manufacturing requirements of springs are nothing more than the three points of machinery, materials, and manufacturing technology. In the industrial age, efficiency and precision are emphasized in everything. In view of this, the design of objects tends to be personalized and lightweight. In order to cope with such changes, the springs’ design and requirements are also more complex and sophisticated. In order to meet these requirements, the machines for manufacturing springs are also changing rapidly. From the initial use of manual molds and mechanical spring machines to multi-axis machines, the main purpose is to conform to the diversified, increasingly complex changes, and small amount demand on springs. Because the spring’s manufacturing has professional skills, the dependence on technicians is relatively high, and the upgrade of the machine can assist the machine operator to overcome the difficulty of manufacturing to meet the needs of the market.

The types of spring materials are spring steel, steel wire, piano wire, stainless steel wire, and oil tempered wire. The use of the material depends on its purpose, such as: high temperature resistance, acid corrosion resistance, and electrical conductivity. You must consider the use of special alloy steel.

In addition to advanced equipment and stable quality materials, the production of springs also depends on the technical capabilities of the operators. They are technicians, also called as setup men. Generally speaking, it takes several years to train the technical personnel. Since the development of springs, some springs have been standardized, but there are still many springs designed for the needs of structural engineers, so the shape is inevitably special or complicated. At this time, in addition to advanced machines, it is also necessary to match experienced setup men.

We mainly manufacture various types of spiral springs, wire springs, wave springs, worm springs and flat springs. In addition to the high insistence on quality, we also strive for perfection in manufacturing technology. Please refer to our main products, we will continue to increase product items and service content, in addition to hope to become your solution provider, and hope to meet your one-stop shopping needs.

In recent years, we have added a number of the most advanced CNC Spring Forming Machines, which have greatly improved the manufacturing efficiency and quality. The sophisticated spring machines make us more comfortable in the production of complicated springs. The following is the manufacturing performance of the machine: